- This topic is empty.

-

AuthorPosts

-

27/02/2025 at 18:08 #2944

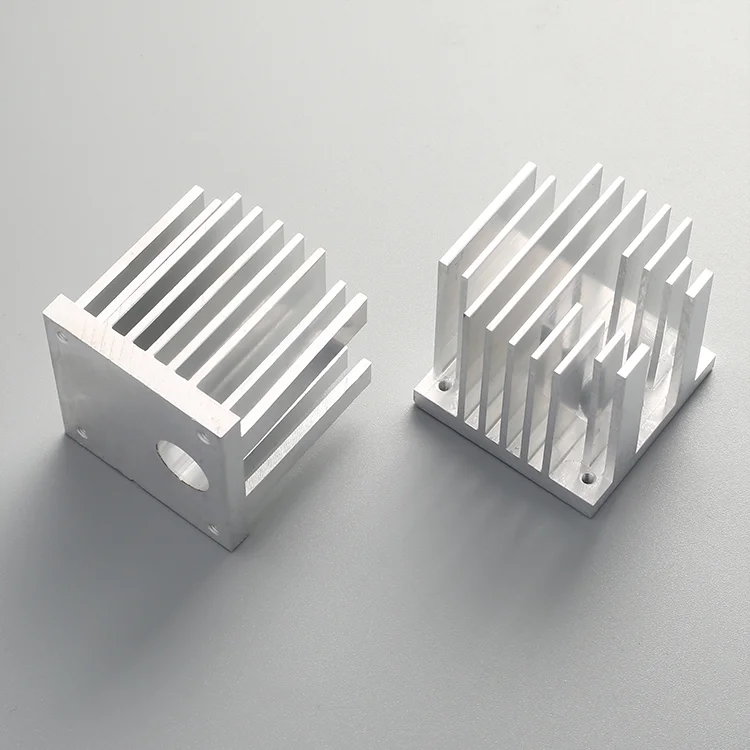

Aluminium extrusion heatsinks play a crucial role in thermal management for various electronic and industrial applications. These components dissipate heat efficiently, ensuring that electronic devices and machinery operate within safe temperature ranges. In this blog post, Vibo, as a professional parts OEM customization service provider, will share the surface treatment process of high precision aluminum extrusion heatsinks for sale to maximize their performance, durability and aesthetics.

Importance of Surface Treatment for Aluminum Extrusion Heatsink

Aluminium extrusion heatsinks are inherently efficient due to the metal' s excellent thermal conductivity and lightweight properties. However, raw aluminium surfaces are prone to oxidation, corrosion, and wear. Without proper surface treatment, these heatsinks may experience performance degradation, reduced lifespan, and poor adhesion for secondary coatings or adhesives. Surface treatment enhances thermal performance, corrosion resistance, electrical insulation, and aesthetic appeal, making it a critical step in the manufacturing process.

Common Surface Treatment Techniques for Aluminium Extrusion Heatsink

Several surface treatment methods are employed to improve the efficiency and durability of aluminium extrusion heatsinks. Below are some of the most common techniques:

1. Anodizing

Anodizing is one of the most popular surface treatment methods for aluminium heatsinks. This electrochemical process forms a controlled oxide layer on the surface of the aluminium, improving corrosion resistance, surface hardness, and electrical insulation.

Benefits of anodizing:

– Enhanced corrosion resistance

– Improved wear resistance

– Electrical insulation properties

– Aesthetic customization with color options

– Better adhesion for adhesives and coatings

Common applications:

– Consumer electronics

– LED lighting systems

– Aerospace and automotive components

2. Powder Coating

Powder coating is a process in which dry powder is electrostatically applied to the heatsink' s surface and then cured under heat. This method provides a durable, high-quality finish that is resistant to chipping, scratching, and corrosion.

Benefits of powder coating:

– Excellent resistance to corrosion and wear

– Wide range of colors and finishes available

– Environmentally friendly (low VOC emissions)

– Improved electrical insulation

Common applications:

– Industrial machinery

– Outdoor electronic enclosures

– Architectural structures

3. Electroplating (Nickel and Tin Plating)

Electroplating involves depositing a thin metal layer, such as nickel or tin, onto the aluminium heatsink. This technique enhances conductivity, corrosion resistance, and solderability.

Benefits of electroplating:

– Improved electrical conductivity

– Enhanced corrosion resistance

– Increased surface hardness

– Good solderability for electronic components

Common applications:

– PCB-mounted heatsinks

– High-frequency RF applications

– Military and aerospace electronics

4. Chemical Conversion Coating (Chromate Coating)

Chemical conversion coating, commonly known as chromate coating, involves applying a chemical treatment that forms a thin protective oxide layer on the aluminium surface. This method is often used as a base layer for further coatings or paint applications.

Benefits of chromate coating:

– Provides moderate corrosion resistance

– Improves paint and adhesive adhesion

– Maintains electrical conductivity

– Cost-effective solution

Common applications:

– Military and aerospace components

– Electrical enclosures

– Automotive parts

5. Sandblasting and Bead Blasting

Sandblasting and bead blasting are mechanical surface treatment techniques that use high-pressure abrasive media to clean and texture the aluminium surface. These methods remove surface contaminants, improve paint adhesion, and create a uniform matte finish.

Benefits of sandblasting and bead blasting:

– Removes oxidation and surface defects

– Provides a uniform and smooth finish

– Improves adhesion for coatings and paints

– Environmentally friendly, as no chemicals are required

Common applications:

– Automotive and aerospace components

– Decorative aluminium products

– Pre-treatment for further coatings

Choosing the Right Surface Treatment of Aluminium Extrusion Heatsink

– Corrosion Resistance: If the heatsink is exposed to moisture, humidity, or harsh environmental conditions, anodizing, powder coating, or electroplating are suitable options.

– Electrical Conductivity: If electrical conductivity is required, avoid anodizing, as it creates an insulating layer. Instead, opt for chromate coating or electroplating.

– Thermal Performance: Anodized surfaces can slightly impact thermal performance due to their insulating properties. If high thermal efficiency is needed, opt for minimal coating thickness or specialized coatings designed for heat dissipation.

– Aesthetic Appeal: If appearance matters, powder coating and anodizing provide customizable finishes in various colors and textures.

Conclusion

The surface treatment of aluminium extrusion heatsinks is an essential step in ensuring optimal performance, durability, and visual appeal. Whether you choose anodizing for corrosion resistance, powder coating for aesthetic appeal, or electroplating for enhanced conductivity, each treatment method offers unique advantages tailored to specific applications. By selecting the right surface treatment, manufacturers can significantly improve the longevity and efficiency of aluminium heatsinks, making them a reliable solution for thermal management in various industries.

-

AuthorPosts

- You must be logged in to reply to this topic.